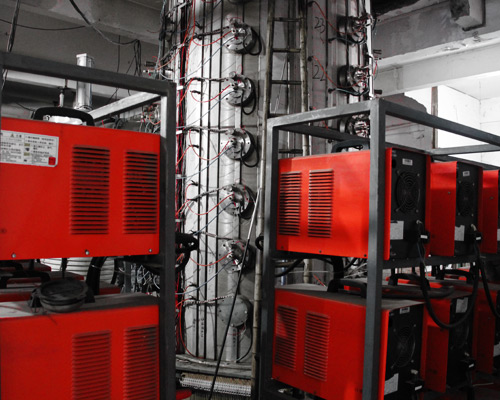

Our technology

PVD Ion Arc Coating is the most technically advanced of all the PVD processes. It provides high durability and scratch resistance than any colour processes.

PVD stands for Physical Vapor Deposition. In the PVD process a solid source material, such as titanium, is atomised into minute molecules. It is then transported in the form of vapor through a vacuum or low pressure gaseous environment to a substrate, where it condenses. The main forms of PVD processes are Vacuum Evaporation, Sputter Deposition and Arc Ion Coating – the most technically advanced of all the PVD technologies.

PVD Ion Coating technology creates an attractive, modern surface in a comprehensive range of colours, including gold, warm copper, antique bronze, greens, blue and even black. It improves the performance of Coloured Stainless Steel by increasing wear, scratch resistance and corrosion resistance, making its durability far superior to conventional coating methods such as electroplating or powder-coating.

The PVD process is also more environmentally friendly than processes such as electroplating and painting, with zero discharge of gas, water waste and other residue.